Fredericks’ Televac® and ETI vacuum measurement brands offer the most innovative and proven vacuum technology on the market including analog and digital vacuum gauges, vacuum sensors, and vacuum controllers, covering the entire vacuum measurement range from just above atmosphere (1000 Torr) to ultra-high vacuum/UHV (10-11 Torr). Televac® also offers pressure measurement up to 10,000 Torr (13 bar). Used in industries ranging from heat treat and vacuum furnaces to national labs and research and development, our vacuum technology is designed to match your needs for your vacuum system. A complete list of all of our vacuum technology is below.

Vacuum controllers, vacuum gauges, cables, accessories, calibration and more for vacuum and pressure measurement

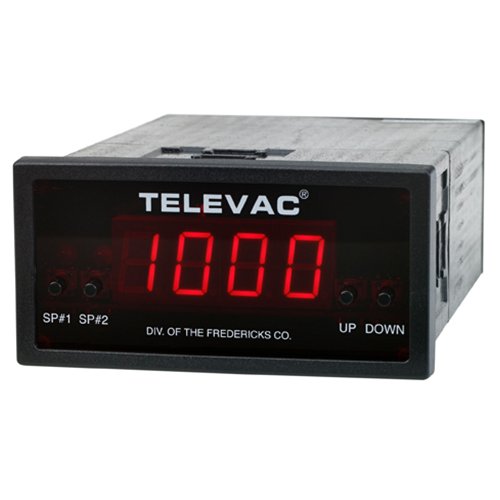

Televac Vacuum Controllers

The Fredericks Company’s Televac® vacuum measurement brand designs and manufactures single channel and multi-channel vacuum controllers (also called a vacuum control unit or vacuum pressure controller) for use with our passive gauges, including thermocouple gauges, convection gauges, and diaphragm gauges for low vacuum measurement, and cold cathode gauges and hot ion gauges for high vacuum measurement.

Each vacuum controller has many features to simplify integration, including analog 0 to 10 V DC outputs for each connected gauge, digital RS-232, RS-485, EthernetIP, and USB communications, and set point relays for process control. Our multi-channel vacuum controllers are highly configurable, connecting to up to 10 passive gauges to give a measurement range of 10-11 Torr to 10,000 Torr.

Some of the most common markets where a vacuum controller is used are heat treat and vacuum furnaces and national labs and research and development.

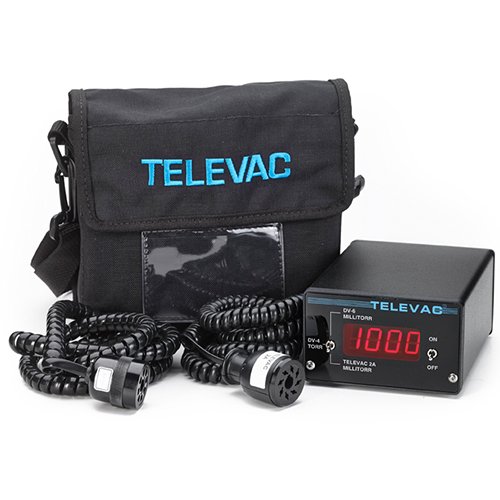

Televac Portable Vacuum Controllers

The Fredericks Company’s Televac® vacuum pressure measurement brand designs and manufactures portable vacuum controllers (also sometimes called a vacuum control unit or vacuum pressure controller, see our handy terminology reference) for use with our 2A thermocouple gauges and DV4 and DV6 thermocouple gauges. We offer two types of portable vacuum pressure controllers; digital vacuum controllers (which have a digital display) and analog vacuum controllers (which have an analog display).

What’s a portable vacuum controller? A portable vacuum control unit is a scaled down (lighter and smaller), battery powered version of our standard vacuum controllers that come with a carrying case and coiled cables to save space. These vacuum controllers only read from one thermocouple gauge at a time, giving them a range of 1 micron (0.001 Torr) to 20 Torr. They’re most commonly used for low vacuum applications like cryogenic and industrial gas storage and the HVAC market.

What are some of the benefits of the 2A thermocouple gauge? The 2A thermocouple gauge has been used in the cryogenic and industrial gas storage industry for decades, testifying to the gauge’s reliability and ruggedness. The filament design and operating temperatures of the 2A thermocouple gauges make it the most contamination resistant passive gauge offered by Televac®.

NIST traceable calibration is also available for all of our portable vacuum controllers. Click here to learn more!

Televac Active Digital Vacuum Gauges

The Fredericks Company’s Televac® vacuum pressure measurement brand designs and manufactures active gauges (also called analog or digital gauges) that combine Televac®’s passive gauges (also called vacuum sensors) and controlling electronics into one compact unit for pressure measurement.

Our active gauges cover the entire practical vacuum range from 10-11 Torr to 1000 Torr and feature bright OLED displays and easy to use touch controls, in addition to RS-485 communications, allowing the user to adjust settings such as measurement units, set points, and calibration directly through the unit’s display or remotely through digital communications.

These active gauges are compact, easy to use, and cost effective solutions for a wide range of vacuum measurement applications, the most common being heat treat and vacuum furnaces, vacuum distillation, thin film deposition, and semiconductor manufacturing equipment.

Looking for full-range vacuum measurement and not sure where to start? Check out our MX4A active convection gauge and our MX7B active cold cathode gauge (also sometimes called a CC gauge), when used together these units provide a measurement range of 10-8 Torr to 1000 Torr. Click here to learn more!

Televac Passive Vacuum Gauges and Vacuum Transducers

The Fredericks Company’s Televac® brand designs and manufactures these gauges (also called a vacuum sensor or a vacuum transducer) including thermocouple gauges, convection gauges (also called Pirani gauges), and diaphragm gauges for low vacuum measurement along with cold cathode gauges (also called Penning ionization gauges) and hot ion gauges for high vacuum measurement.

We’ve designed all of our vacuum transducers to be cost-effective, robust, contamination resistant, and optimized for a variety of applications and environments. Some of the most common markets where our units are used are heat treat and vacuum furnaces, national labs and research and development, and cryogenics and industrial gases.

Cables

Televac® cables are used to connect passive gauges to controllers, or to connect active gauges to your vacuum system. Many standard cable lengths are available, with cables as long as 300 ft (91 m) for larger vacuum systems. Our robust gauge cables are designed to be plugged and un-plugged extensively over their lifetime, with built-in strain relief and durable connectors to prevent damage or breakage over years of use.

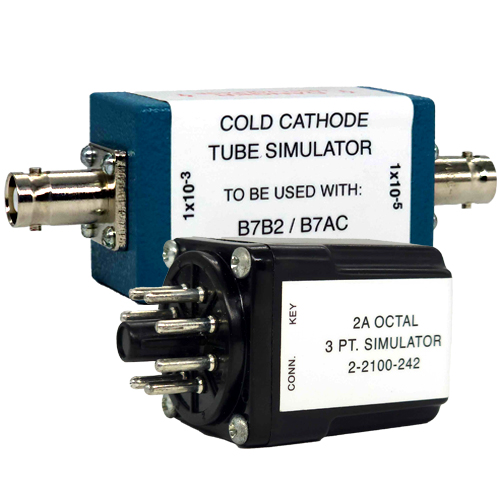

Accessories

Televac® accessories include a variety of spare parts for our vacuum technology along with vacuum sensor filters and vacuum sensor simulators. Filter vacuum technology helps prevent contamination of your gauges, extending their life, reducing the need for cleaning, and keeping the gauge accuracy in tolerance for longer, all meaning that you spend less money on gauge maintenance. Vacuum sensor simulators can be used to diagnose many different issues with vacuum controller and active gauge electronics, providing an electrical signal which is equivalent to a typical passive gauge at various pressures.

ETI Hot Ion

Our ETI brand offers various types of vacuum technology including glass and nude hot ion gauges (also called a hot filament, Bayard-Alpert, BA, or BAG gauges or vacuum sensors) for high-vacuum measurement from 10-10 Torr to 10-3 Torr using tungsten filaments. This vacuum technology is popular in the semiconductor industry for the higher accuracy it offers over cold cathode vacuum technology. While hot ion gauges provide better accuracy than cold cathode gauges, hot ion gauges are also more expensive, cannot be cleaned, and are more susceptible to contamination so they don’t last as long.

Vacuum Calibration Services

We offer comprehensive vacuum calibration services for all our vacuum gauging equipment, including various calibration options to suit your specific needs. Our vacuum calibration services encompass both factory vacuum calibration and NIST traceable vacuum calibration, as well as ISO 17025 Accredited calibrations for all our active gauges and controllers, complemented by passive gauges. Notably, our vacuum calibration services are known for their efficiency, with significantly shorter lead times than competitors. Upon receiving your equipment, our turnaround times typically range from 1 to 2 weeks, and expedited services are also available for those with more urgent requirements. Additionally, if you encounter any issues with your vacuum equipment, we offer the convenience of sending it back to us for evaluation and necessary repairs and service. This comprehensive approach underscores our commitment to providing top-quality calibration services tailored to your specific industry and application needs.

Legacy Televac Products

We still manufacture the legacy products listed below, however, we also have newer products that have replaced these legacy products. If you click on a legacy product page, you’ll see the new replacement product. If you have a vacuum system that uses a legacy product, please feel free to contact us to discuss the best options for upgrading.