- Vacuum controller for up to (4) Televac® MX active vacuum gauges and (1) CDG

- EthernetIP connections to the Televac® MX2A, MX4A, MX7B, and MX7M Active Vacuum Gauges

- Low cost, standard Cat5e cables for vacuum gauge connections

- Significantly reduces latency from analog signals (HMI/vacuum gauge display mismatch)

- Digitally calibrate vacuum gauges from your HMI

- Configure all settings for Televac® MX series active vacuum gauges

- 24 V DC power supply to power gateway and connected vacuum gauges

- Optional ±15 V DC power supply connections for CDGs

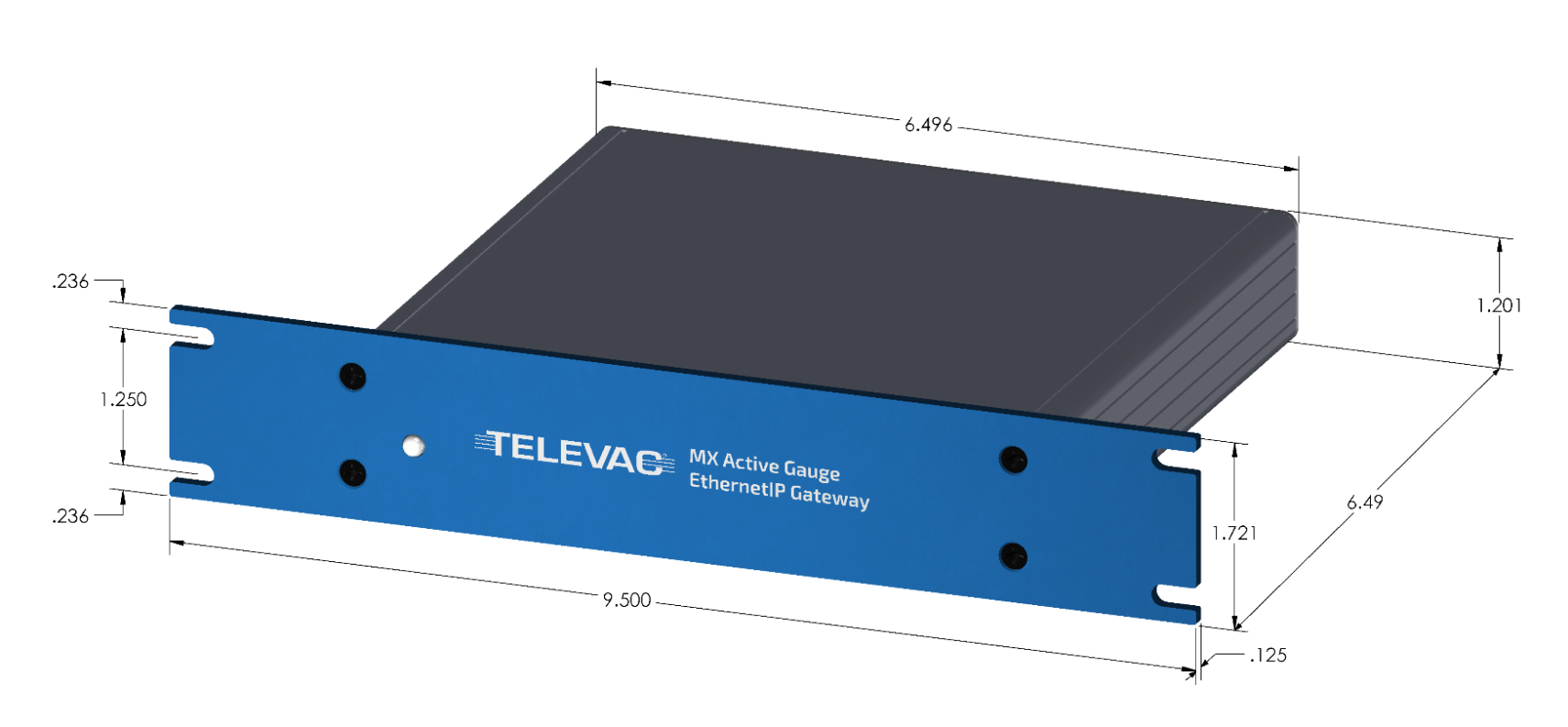

- Rack and panel mountable

- EthernetIP for simple connection of your vacuum pressure controller to a PC, PLC, and other equipment

- Class 1 (cyclic) and Class 3 (acyclic) connections supported

- Programmable IP address and DHCP enable/disable

- 10/100 Mbit, half or full duplex port operation

- Field upgradeable firmware via USB

- Status LEDs for network/module status/port data activity

- Secure web access for network and gateway data and settings via a web browser

- Excellent customer support

The MX Active Gauge EthernetIP Gateway (sometimes also called an EthernetIP vacuum controller, EthernetIP vacuum control unit, or EthernetIP vacuum pressure controller) is the first and only solution designed to provide an EthernetIP connection between Televac® active vacuum gauges and Rockwell Automation® Allen-Bradley® PLCs. An increasingly popular industrial network communication standard, EthernetIP communication offers users faster and more reliable vacuum measurements and eliminates the need for additional analog-to-digital converters or other vacuum controllers and vacuum pressure controllers.

EthernetIP Vacuum Controller Gateway Compatible Active Vacuum Gauges

This EthernetIP vacuum control unit supports an easily configurable network of up to (4) Televac® active vacuum gauges and (1) capacitance diaphragm vacuum gauge (CDG) through EthernetIP communications. Multiple gateways can also be daisy-chained together for additional vacuum gauge connections (made possible by dual EthernetIP ports on the back of the unit). The gateway allows users to interface directly with supported PLCs and PCs, including the ability to read vacuum measurements and change vacuum gauge settings from a convenient, remote location without complicated conversion tools. In addition to Televac vacuum gauges, the gateway supports CDGs from MKS, Inficon, Leybold, Brooks, and Setra. 24 V DC and ±15 V DC with D-sub 15 (DB15) and D-sub 9 (DB9) connectors are supported.

MX Active Gauge EthernetIP Gateway

RJ45 Adapters

Cat5e Ethernet Cables

Using the Gateway for Heat Treat and Vacuum Furnace Applications

This vacuum controller gateway is particularly useful for heat treat and vacuum furnace applications where a single gateway can eliminate the need for up to (5) analog-to-digital converter (ADC) input channels while simultaneously reducing any latency from analog-to-digital conversions (causing a mismatch between the vacuum gauge display and the furnace human-machine-interface or HMI). The EthernetIP vacuum controller gateway also gives the end user the ability to calibrate their vacuum gauges from their HMI by interfacing digitally with the vacuum controller gateway. This means no more climbing on top of your furnace to do vacuum measurement comparisons! The ability to change settings and calibrate digitally is due to the unique design of the vacuum controller gateway, where all communication with Televac® vacuum gauges is done digitally (via RS-485).

More Information and Similar Products

Essentially, you can think of the EthernetIP vacuum pressure controller gateway as a fancy RS-485 to EthernetIP converter. The exception to this is the CDG input, which takes the 0 to 10 V DC analog output of the CDG and converts it to a digital value (using an analog-to-digital converter) which can then be read over EthernetIP. If you’re looking for an EthernetIP vacuum controller/vacuum control unit solution (instead of active vacuum gauges and the gateway) check out our MX200 EthernetIP!

| Operating Range | 5*10-11 Torr to 1*104 Torr |

| Communications (External) | EthernetIP |

| Communications (Active Gauges) | RS-485 |

| Active Gauge RS-485 Addresses | 1 to 4 |

| Active Gauge RS-485 Baud | 38400 |

| Supply Voltage | 22 V DC to 26 V DC |

| Maximum Power | 30 W max |

| Operating Temperature | 0 °C to 50 °C |

| Storage Temperature | -20 °C to 70 °C |

| Maximum Active Gauges Controlled | 4 |

| Maximum CDGs Controlled | 1 |

| Response Time | ≤100 ms |

| P1 | EthernetIP RJ45 port 1 to PLC/PC |

| P2 | EthernetIP RJ45 port 2 to PLC/PC |

| NS | Network status LED |

| MS | Module status LED |

| 1 | Active gauge 1 connection |

| 2 | Active gauge 2 connection |

| 3 | Active gauge 3 connection |

| 4 | Active gauge 4 connection |

| CDG | CDG connection |

| 24 | +24 V DC supply |

| GND | Ground Supply |

| +15 | +15 V DC supply for CDG (optional) |

| -15 | -15 V DC supply for CDG (optional) |

| BTLD | Bookload button |

| USB | USB communication for bootloading |

| Connectors | (2) RJ45 |

| Ports | 10/100 Mbit, half or full duplex |

| DHCP | Enable or disable |

| Class 1 Connections | |

| Connection Type | Point-to-point, multicast |

| Target to Originator Instance ID | 100 |

| Data Size | 20 |

| Originator to Target Instance ID | 150 |

| Data Size | 4 |

| Configuration Instance | 3 |

| Supported Connections | 4 |

| Requested Packet Interval | 1 ms to 3200 ms |

| Trigger Types | Cyclic, change of state |

| Priorities | Low, high, schedule, urgent |

| Class 3 Connections | |

| Service | 0xE (get), 0X10 (set) |

| Class | 0xA2 |

| Instance | See ADI table |

| Data Value Attribute | 5 |

| Supported Connections | 6 |

| Requested Packet Interval | 100 ms to 10000 ms |

| Connection Type | Point-to-point |

| Trigger Type | Application |

| Priority | Low |

Please refer to the instruction manual for a complete list of Class 1 and Class 3 connection details, a complete list of ADIs, and information about the Electronic Data Sheet (EDS) file.

The RJ45 connectors labeled P1 and P2 are the EthernetIP connections that will run to the PLC or PC. The RJ45 connectors labeled 1 through 4 are the active gauge inputs. These will run through Cat5e Ethernet cables and through an adapter to attach to the active gauges in the network. All active gauges must be set to separate RS-485 addresses 1 through 4 and baud rate 38400 to communicate with the gateway. The RJ45 connector labeled CDG will connect to the CDG in the network if one is available. The CDG must be turned on through the appropriate parameter in the ADI table.

The power input connector accepts a +24 V DC and GND connection, as well as an optional ±15 V DC input to run to the attached CDG if required. Regardless of the alternate supply, the gateway and attached active gauges require the +24 V DC input to be connected in order to operate. The pushbutton labeled BTLD is to be pressed while powering the gateway to send the unit into bootload mode for the ability to easily update the firmware, and the update occurs over the USB connection.

| Enclosure | Aluminum |

| Electrical Connections | 4-pin connector |

| Weight | 0.65 kg (1.4 lbs) |

| Certified to UL 61010-1 |

| Certified to CAN/CSA C22.2 No. 61010-1-12 |

| CE certified to EN 61010-1, EN 61236-1, EN 55011 |

| RoHS compliant |

| IP40 |

| EAC certified |

| NIST traceable calibration optional |

Product Documentation

| MX Active Gauge EthernetIP Gateway Datasheet |

| MX Active Gauge EthernetIP Gateway Instruction Manual |

| MX Active Gauge EthernetIP Gateway EDS File |

| Televac® Vacuum Calibration Tolerances |

Application Notes

Tools

| Vacuum Leak Rate Converter |

| Vacuum Measurement Converter |

Articles

| Vacuum Measurement Using Modern Cold Cathode Technology |

Brochures

| Televac® Vacuum Measurement Product Catalog |

MX Active Gauge EthernetIP

Gateway Quantity Discounts

| Quantity | Discount |

| 1 | List |

| 5 | 5% |

| 15 | 10% |

| 25+ | 15% |

Cat5e Ethernet Cable Quantity

Discounts

| Quantity | Discount |

| 1 | List |

| 50 | 5% |

| 75 | 10% |

| 100+ | 15% |