프레더릭스의 전해질 틸트 센서를 통해 세계에서 가장 에너지 효율적인 무선 모니터링 솔루션 제공

소개

There are over 612,000 bridges in the United States and as of February 2017, almost 10% of them need to be repaired or replaced according to The American Road and Transportation Builders Association. That means that there are currently over 55,000 bridges that require real-time monitoring in order to avoid a catastrophe like the 2007 bridge collapse in Minneapolis, Minnesota.

레센시스란?

Resensys는 이러한 및 기타 고속도로 교량의 구조적 안정성을 평가하는 데 도움이 되는 비용 효율적이고 확장 가능한 솔루션을 제공하여 구조적 문제를 파악하고 필요한 유지 보수 및 수리를 계획하여 교량 안전성과 수명을 보장할 수 있도록 지원합니다.

무선 구조 상태 모니터링 솔루션인 SenSpot™는 건설 중인 기존 교량 및 교량용으로, 교량 성능에 영향을 미치는 다양한 변수를 측정하는 작고 저렴한 설치가 용이한 무선 센서를 갖추고 있습니다.

메릴랜드 대학의 사장 겸 CTO 박사 메디 칸다니 (Mehdi Khandani)가 수행 한 연구에서 태어난 Resensys는 실시간 지질 구조 모니터링의 선두 주자이며 최소 10 년의 예상 수명을 가진 가장 내구성이 뛰어난 무선 교량 모니터링 시스템을 제공합니다. 자세한 내용은 http://www.resensys.com방문하십시오.

The Challenge

인프라 모니터링을 위한 다른 센서가 있지만 Resensys 장치를 차별화하는 것은 약 4마이크로와트만 사용하거나 일반적인 전구보다 약 1억 배 적은 초저전력 소비입니다. 즉, SenSpot 센서의 수명은 10년 동안 작은 1/2-AA 배터리만 사용하여 최소 수명을 가지고 있습니다.

이러한 효율적이고 정확한 모니터링 시스템을 제공하기 위해 Resensys는 최대 천 도의 해상도를 갖춘 틸트 센서를 찾는 동시에 낮은 전력 소비, 내구성 및 최소 10년의 제품 수명을 제공해야 했습니다.

솔루션

Dr. Khandani and his team thoroughly evaluated a variety of MEMS and other electrolytic tilt sensors and concluded that the Fredericks Single-Axis Narrow-Range Electrolytic Tilt Sensor (PN 0703-0711-99) significantly outperformed competing products in terms of long term repeatability and resolution.

“Qualitatively, Fredericks’ devices were an order of magnitude better than both MEMS and competing electrolytic sensors,” says Dr. Khandani. “In our application, repeatability is very important and none of the competing products did as great as Fredericks products did.”

결과

With the help of Fredericks’ electrolytic tilt sensors, Resensys is able to offer the world’s most energy-efficient wireless monitoring solution that helps keep travelers safe with around 5,000 SenSpot™ tilt units in use in the US and around the world.

“Our decision to use Fredericks products was driven by the excellent accuracy and durability of their tilt sensors,” Dr. Khandani adds. “Such long term and high-quality measurements help capture the smallest movement and instability on critical bridge components.”

센스팟™ 실천: 파타프스코 강 다리

In the Spring of 2014, cracks were spotted in the girders and piers of the I-70 Patapsco River Bridge near Baltimore, Maryland. Engineers found that non-responsive bearings had caused damage to piers and steel girders of the bridge, which led to its closure in June 2014.

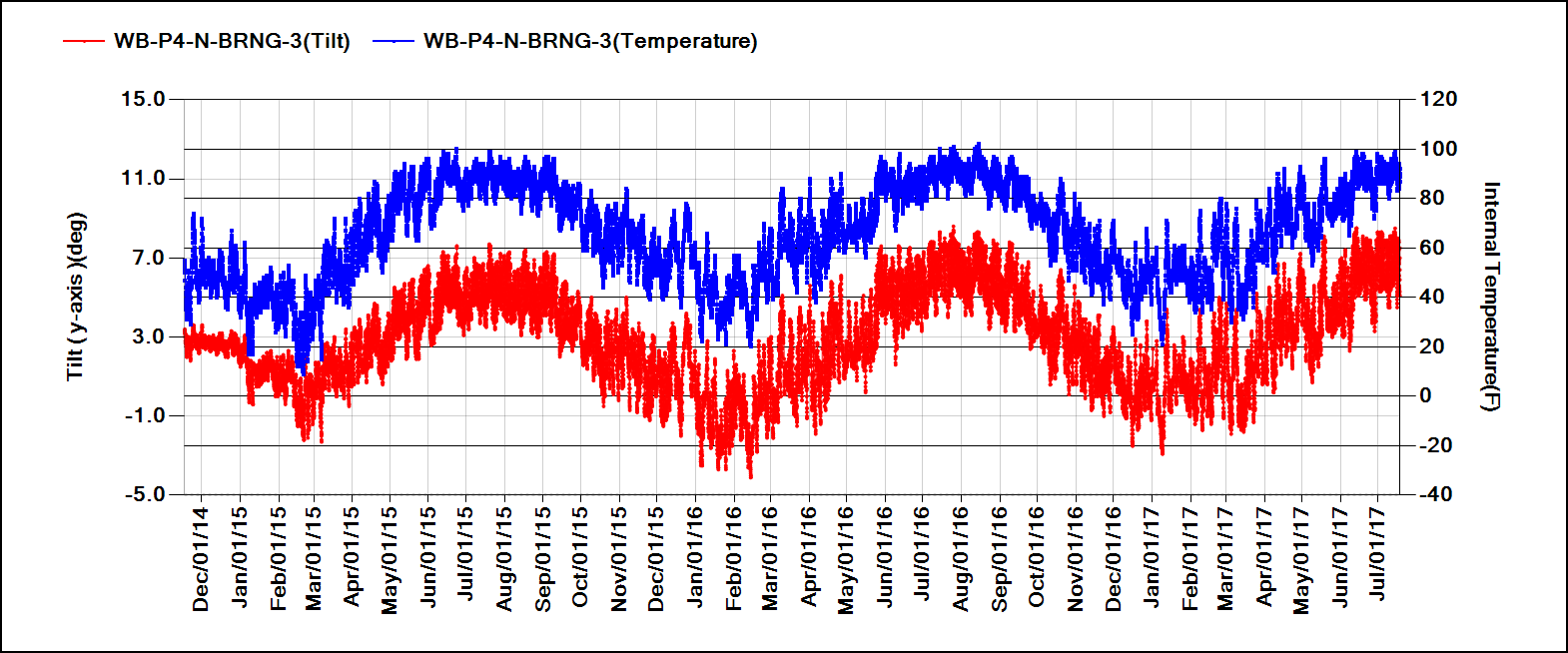

Repairs were made, retrofits were applied, and a SenSpot™ monitoring system was installed in July 2014 to detect any further changes. More than 40 SenSpot™ units were mounted on the bridge, including 12 tilt sensors located on the bridge’s rocker bearings to monitor the movement pattern and detect non-responsiveness or over-responsiveness. In addition, six high-resolution tilt sensors were mounted on the bridge’s piers to monitor the deflection and rotation of the bridge rocker bearings caused by cold temperatures.

Early results from August to November 2014 found that the bearings on two piers were non-responsive to temperature changes and an additional bearing saw only 20% of expected movement. Data collected through Spring 2015, however, showed that the bearings had an unprecedented response to the robust retrofits (combined with especially cold winter), and by March 2015 all piers and respective bearings were fully responsive.

Dr. Khandani notes, “After more than four years of continuous monitoring, we are pleased that the Fredericks devices used in SenSpot™ sensors produce very consistent, repeatable, and high-quality measurements of tilt and inclination at sub-arc-second resolution.”

Before alerting the Maryland State Highway Administration, the Resensys team worked with engineers at Fredericks to confirm the data. At Fredericks, we take a partnership approach to our relationships with customers, and customer satisfaction is a priority. We have dedicated representatives and engineers committed to providing highly responsive service, and our customers have anytime-access to our leadership team, made possible in part by our “not too big, not too small” operation.