フレデリックス社の電解傾斜センサの助けを借りて、世界で最もエネルギー効率の高いワイヤレスモニタリングソリューションを提供

序章

There are over 612,000 bridges in the United States and as of February 2017, almost 10% of them need to be repaired or replaced according to The American Road and Transportation Builders Association. That means that there are currently over 55,000 bridges that require real-time monitoring in order to avoid a catastrophe like the 2007 bridge collapse in Minneapolis, Minnesota.

Resensysとは何ですか?

レセンシスは、これらの高速道路橋やその他の高速道路橋の構造安定性を評価するための費用対効果の高いスケーラブルなソリューションを提供しており、構造上の問題をピンポイントで特定し、橋の安全性と寿命を確保するために必要なメンテナンスや修理を計画することができます。

同社の無線構造健全性モニタリングソリューションであるSenSpot™は、既存の橋梁や建設中の橋梁向けで、小型で低コスト、設置が簡単な無線センサーを搭載しており、橋梁の性能に影響を与える様々な変数を測定します。

メリーランド大学の社長兼CTOのMehdi Khandani博士が行った研究から生まれたResensysは、リアルタイムの地中構造物モニタリングのリーダーであり、最低期待寿命10年の最も耐久性の高い無線橋梁モニタリングシステムを提供しています。詳細については、http://www.resensys.com をご覧ください。

The Challenge

インフラ監視用のセンサーは他にも市場に出回っていますが、Resensysのデバイスを差別化しているのは、消費電力が約4マイクロワットと、一般的な電球の約1億分の1にも満たない超低消費電力であることです。これは、SenSpotセンサーの寿命が1/2-AAの小型バッテリーのみで10年以上であることを意味しています。

このような効率的で正確なモニタリングシステムを提供するために、Resensysは、低消費電力、耐久性、製品寿命10年以上の製品を提供しながら、最大1,000分の1度の分解能を持つ傾斜センサーを見つける必要がありました。

解決策

Dr. Khandani and his team thoroughly evaluated a variety of MEMS and other electrolytic tilt sensors and concluded that the Fredericks Single-Axis Narrow-Range Electrolytic Tilt Sensor (PN 0703-0711-99) significantly outperformed competing products in terms of long term repeatability and resolution.

“Qualitatively, Fredericks’ devices were an order of magnitude better than both MEMS and competing electrolytic sensors,” says Dr. Khandani. “In our application, repeatability is very important and none of the competing products did as great as Fredericks products did.”

結果

With the help of Fredericks’ electrolytic tilt sensors, Resensys is able to offer the world’s most energy-efficient wireless monitoring solution that helps keep travelers safe with around 5,000 SenSpot™ tilt units in use in the US and around the world.

“Our decision to use Fredericks products was driven by the excellent accuracy and durability of their tilt sensors,” Dr. Khandani adds. “Such long term and high-quality measurements help capture the smallest movement and instability on critical bridge components.”

SenSpot™の動作。パタプスコ川橋

In the Spring of 2014, cracks were spotted in the girders and piers of the I-70 Patapsco River Bridge near Baltimore, Maryland. Engineers found that non-responsive bearings had caused damage to piers and steel girders of the bridge, which led to its closure in June 2014.

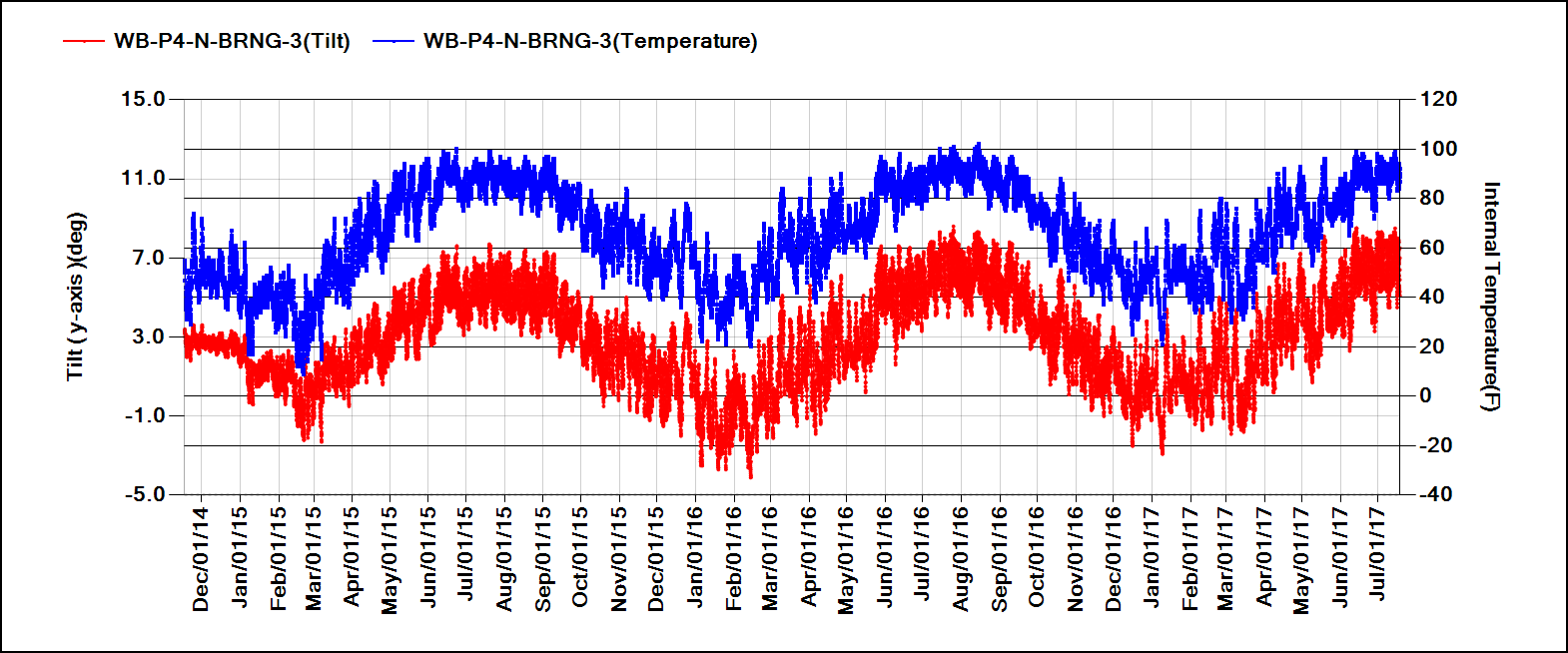

Repairs were made, retrofits were applied, and a SenSpot™ monitoring system was installed in July 2014 to detect any further changes. More than 40 SenSpot™ units were mounted on the bridge, including 12 tilt sensors located on the bridge’s rocker bearings to monitor the movement pattern and detect non-responsiveness or over-responsiveness. In addition, six high-resolution tilt sensors were mounted on the bridge’s piers to monitor the deflection and rotation of the bridge rocker bearings caused by cold temperatures.

Early results from August to November 2014 found that the bearings on two piers were non-responsive to temperature changes and an additional bearing saw only 20% of expected movement. Data collected through Spring 2015, however, showed that the bearings had an unprecedented response to the robust retrofits (combined with especially cold winter), and by March 2015 all piers and respective bearings were fully responsive.

Dr. Khandani notes, “After more than four years of continuous monitoring, we are pleased that the Fredericks devices used in SenSpot™ sensors produce very consistent, repeatable, and high-quality measurements of tilt and inclination at sub-arc-second resolution.”

Before alerting the Maryland State Highway Administration, the Resensys team worked with engineers at Fredericks to confirm the data. At Fredericks, we take a partnership approach to our relationships with customers, and customer satisfaction is a priority. We have dedicated representatives and engineers committed to providing highly responsive service, and our customers have anytime-access to our leadership team, made possible in part by our “not too big, not too small” operation.