- Vacuum controller for up to (4) Televac® MX active vacuum gauges and (1) CDG

- EthernetIP connections to the Televac® MX2A, MX4A, MX7B, and MX7M Active Vacuum Gauges

- Câbles Cat5e standard et peu coûteux pour les connexions des jauges à vide

- Réduit considérablement la latence des signaux analogiques (décalage entre l'affichage de l'IHM et celui de la jauge à vide)

- Étalonnage numérique des jauges à vide à partir de votre IHM

- Configure all settings for Televac® MX series active vacuum gauges

- Alimentation électrique 24 V DC de la passerelle d'alimentation et des vacuomètres connectés

- En option, connexions d'alimentation électrique de ±15 V DC pour les GDC

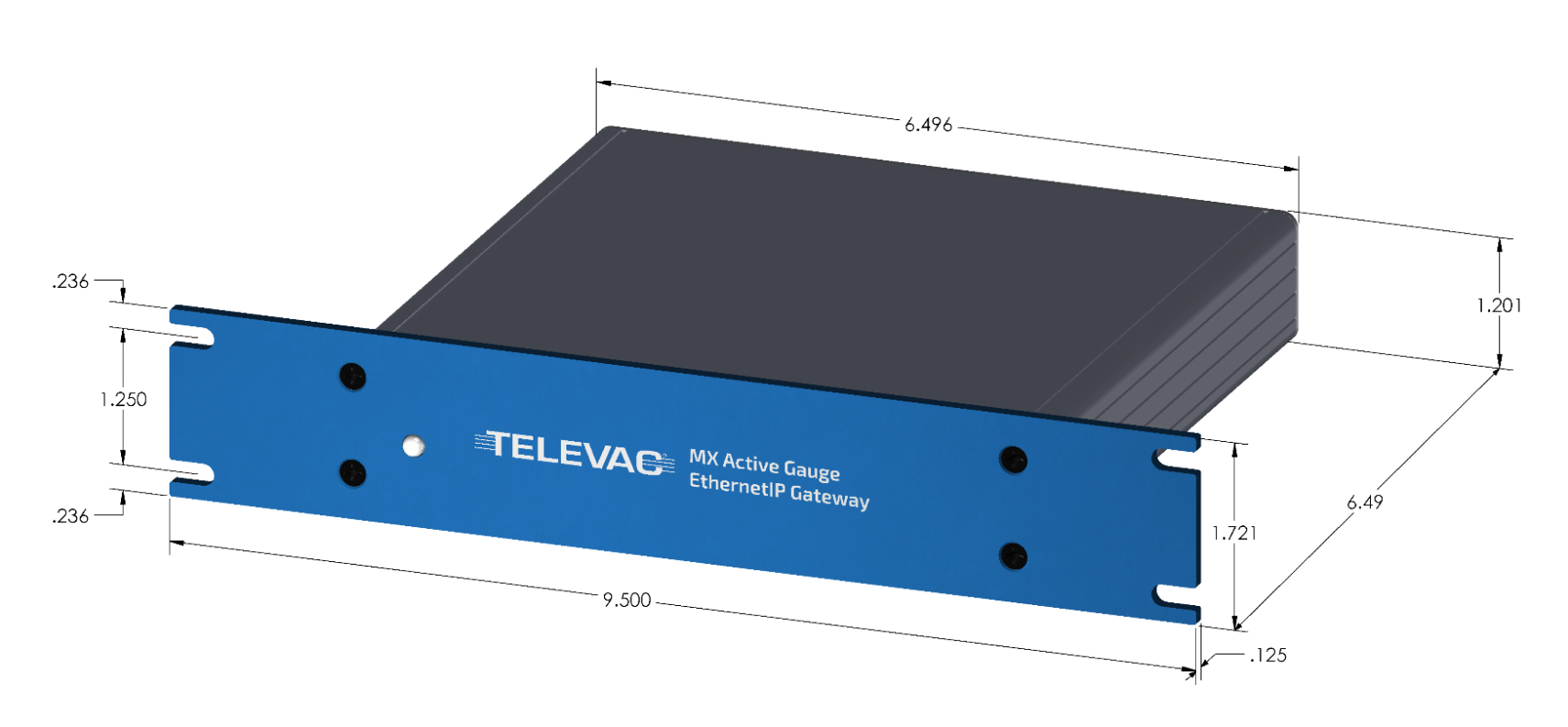

- Montage en rack et en panneau

- EthernetIP pour une connexion simple de votre contrôleur de pression de vide à un PC, un PLC et d'autres équipements

- Les connexions de classe 1 (cyclique) et de classe 3 (acyclique) sont prises en charge

- Activation/désactivation de l'adresse IP programmable et du DHCP

- 10/100 Mbit, fonctionnement en duplex intégral ou partiel

- Micrologiciel extensible sur le terrain via USB

- LED d'état pour l'état du réseau/module/activité des données portuaires

- Accès web sécurisé pour les données et les paramètres du réseau et de la passerelle via un navigateur web

- Un excellent service à la clientèle

Passerelle EthernetIP à jauge active MX

Adaptateurs RJ45

Cat5e Ethernet Cables

| Gamme de fonctionnement | 5*10-11 Torr to 1*104 Torr |

| Communications (External) | EthernetIP |

| Communications (Active Gauges) | RS-485 |

| Adresses RS-485 à jauge active | 1 to 4 |

| Jauge active RS-485 Baud | 38400 |

| Tension d'alimentation | 22 V DC à 26 V DC |

| Puissance maximale | 30 W max |

| Température de fonctionnement | 0 °C à 50 °C |

| Température de stockage | -20 °C à 70 °C |

| Maximum Active Gauges Controlled | 4 |

| Maximum de CDG contrôlés | 1 |

| Temps de réponse | ≤100 ms |

| P1 | EthernetIP RJ45 port 1 to PLC/PC |

| P2 | EthernetIP RJ45 port 2 to PLC/PC |

| NS | Network status LED |

| MS | Module status LED |

| 1 | Active gauge 1 connection |

| 2 | Active gauge 2 connection |

| 3 | Active gauge 3 connection |

| 4 | Active gauge 4 connection |

| CDG | CDG connection |

| 24 | +24 V DC supply |

| GND | Ground Supply |

| +15 | +15 V DC supply for CDG (optional) |

| -15 | -15 V DC supply for CDG (optional) |

| BTLD | Bookload button |

| USB | USB communication for bootloading |

| Connectors | (2) RJ45 |

| Ports | 10/100 Mbit, half or full duplex |

| DHCP | Enable or disable |

| Class 1 Connections | |

| Connection Type | Point-to-point, multicast |

| Target to Originator Instance ID | 100 |

| Data Size | 20 |

| Originator to Target Instance ID | 150 |

| Data Size | 4 |

| Configuration Instance | 3 |

| Supported Connections | 4 |

| Requested Packet Interval | 1 ms to 3200 ms |

| Trigger Types | Cyclic, change of state |

| Priorities | Low, high, schedule, urgent |

| Class 3 Connections | |

| Service | 0xE (get), 0X10 (set) |

| Class | 0xA2 |

| Instance | See ADI table |

| Data Value Attribute | 5 |

| Supported Connections | 6 |

| Requested Packet Interval | 100 ms to 10000 ms |

| Connection Type | Point-to-point |

| Trigger Type | Candidature |

| Priority | Faible |

Please refer to the instruction manual for a complete list of Class 1 and Class 3 connection details, a complete list of ADIs, and information about the Electronic Data Sheet (EDS) file.

The RJ45 connectors labeled P1 and P2 are the EthernetIP connections that will run to the PLC or PC. The RJ45 connectors labeled 1 through 4 are the active gauge inputs. These will run through Cat5e Ethernet cables and through an adapter to attach to the active gauges in the network. All active gauges must be set to separate RS-485 addresses 1 through 4 and baud rate 38400 to communicate with the gateway. The RJ45 connector labeled CDG will connect to the CDG in the network if one is available. The CDG must be turned on through the appropriate parameter in the ADI table.

The power input connector accepts a +24 V DC and GND connection, as well as an optional ±15 V DC input to run to the attached CDG if required. Regardless of the alternate supply, the gateway and attached active gauges require the +24 V DC input to be connected in order to operate. The pushbutton labeled BTLD is to be pressed while powering the gateway to send the unit into bootload mode for the ability to easily update the firmware, and the update occurs over the USB connection.

| Pièce jointe | Aluminium |

| Connexions électriques | Connecteur à 4 broches |

| Poids | 0,65 kg (1,4 lbs) |

| Certifié selon UL 61010-1 |

| Certifié selon CAN/CSA C22.2 No. 61010-1-12 |

| Certifié CE selon EN 61010-1, EN 61236-1, EN 55011 |

| Conforme à la directive RoHS |

| IP40 |

| Certifié EAC |

| Calibrage traçable par le NIST en option |

Documentation sur les produits

Notes d'application

Outils

| Vacuum Leak Rate Converter |

| Convertisseur de mesure du vide |

Articles

| Mesure du vide à l'aide de la technologie moderne des cathodes froides |

Brochures

| Televac® Vacuum Measurement Product Catalog |

MX Active Gauge EthernetIP

Gateway Quantity Discounts

| Quantité | Remise |

| 1 | Liste |

| 5 | 2% |

| 10 | 5% |

| 15 | 7% |

| 20 | 10% |

| 25 | 13% |

| 30+ | 15% |

Cat5e Ethernet Cable Quantity

Discounts

| Quantité | Remise |

| 1 | Liste |

| 50 | 5% |

| 75 | 10% |

| 100+ | 15% |

Using the Gateway for Heat Treat and Vacuum Furnace Applications

This vacuum controller gateway is particularly useful for heat treat and vacuum furnace applications where a single gateway can eliminate the need for up to (5) analog-to-digital converter (ADC) input channels while simultaneously reducing any latency from analog-to-digital conversions (causing a mismatch between the vacuum gauge display and the furnace human-machine-interface or HMI). The EthernetIP vacuum controller gateway also gives the end user the ability to calibrate their vacuum gauges from their HMI by interfacing digitally with the vacuum controller gateway. This means no more climbing on top of your furnace to do vacuum measurement comparisons! The ability to change settings and calibrate digitally is due to the unique design of the vacuum controller gateway, where all communication with Televac® vacuum gauges is done digitally (via RS-485).

Plus d'informations et produits similaires

En gros, on peut considérer la passerelle de contrôleur de pression de vide EthernetIP comme un convertisseur RS-485 vers EthernetIP. L'exception est l'entrée CDG, qui prend la sortie analogique 0 à 10 V DC du CDG et la convertit en une valeur numérique (à l'aide d'un convertisseur analogique-numérique) qui peut ensuite être lue sur EthernetIP. Si vous recherchez une solution de contrôleur de vide / unité de contrôle de vide EthernetIP (au lieu des vacuomètres actifs et de la passerelle), consultez notre MX200 EthernetIP !